Cost of quality

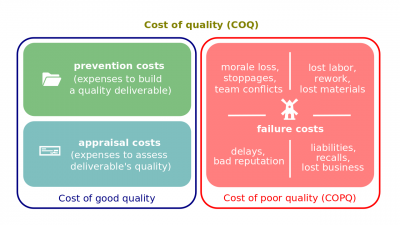

Cost of quality (also known by its acronym, COQ; hereinafter, the Cost) is two parts of all the costs incurred to ensure quality. These two parts are:

- Cost of good quality (also known as costs of conformance), which are money spent to avoid failures or, in other words, to keep the work products defect-free. They include prevention and appraisal costs.

- Cost of poor quality (also known by its acronym, COPQ, as well as failure cost, costs of non-conformance, or costs of failure of conformance), which are money spent because of failures or, in other words, of failure of keeping the work products defect-free. They include tangible and intangible internal (i.e. before the market exchangeable reaches the customer) and external (i.e. after the market exchangeable reaches the customer) costs.

The PAF paradigm is another name that represents the concept of the Cost; PAF is the acronym for prevention, appraisal, failure.

Contents

Trivia

Definitions

According to Managing Quality by Foster (6th edition),

- PAF paradigm. Refers to prevention, appraisal, and failure costs of quality.

According to Cost Accounting by Horngren, Datar, Rajan (14th edition),

- Costs of quality (COQ). Costs incurred to prevent, or the costs arising as a result of, the production of a low-quality product.

Total cost

- Main wikipage: Three spheres of quality

- The Cost is a part of the total cost of quality (also known as costs of quality and quality costs). The total cost includes both the Cost and those expenses on quality management that the Cost excludes. The three spheres of quality depict this circumstance.

Cost of good quality

Cost of good quality or costs of conformance are money spent to avoid failures or, in other words, to keep the produced market exchangeables defect-free. These costs include prevention and appraisal costs.

Appraisal costs

- Main wikipage: Appraisal cost

- Appraisal costs (also known as quality control costs) are those expenses that are related to auditing, evaluating, measuring, and testing the work products or, in other words, costs to assess the quality of the completed work product. These costs include destructive testing loss, inspection, as well as product audit, evaluation, and testing expenses.

Prevention costs

- Main wikipage: Prevention cost

- Prevention costs (also known as quality assurance costs) are those expenses that are related to the prevention of poor quality in the work products or, in other words, costs to build a quality work product. These expenses include benchmarking, customer feedback collecting, process documentating, equipment, quality circle time, quality systems research, site audits, tools, and training.

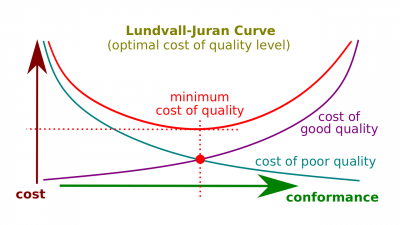

Optimal Cost

The optimal Cost is one that reflects the appropriate balance for investing in the cost of good quality and cost of poor quality. Some models such as the Lindvall-Juran Curve indicate that the optimal quality cost is the point in which investing in additional prevention and appraisal costs is neither beneficial nor cost effective.

Cost of poor quality

- Main wikipage: Cost of poor quality

- Cost of poor quality (also known by its acronym, COPQ, as well as failure cost, costs of non-conformance, or costs of failure of conformance) is money spent because of failures or, in other words, of failure of keeping produced market exchangeables defect-free. According to Juran's Quality Handbook by Defeo (7th edition),

These costs include tangible and intangible internal (i.e. before the marketable reaches the customer) and external (i.e. after the marketable reaches the customer) expenses.Cost of poor quality (COPQ). The costs that would disappear in the organization if all failures were removed from a product, service, or process; typically measures of a percent of sales or total costs.

Lindvall-Juran Curve

- The Lindvall-Juran Curve depicts the hypothesis that the Cost is economically the lowest and the conformance level is considered optimal when the cost of good quality and cost of poor quality are equal.